Definition of product levels for easy blade selection

Success in the cutting process is determined by the correct combination of different factors governed by the cutting dynamics and the machine which powers the blade.

Taking into account that a change in only one of these factors will influence the final result, SEKTOR CUTTING EXPERT has chosen to present its products using a simplified classification system.

Our LEVELS determine blade characteristics that are in line with the evaluation of the saw machine’s performance and the priority of cutting parameter desired by the customer.

The classification for blade uses are: LEVEL 3, LEVEL 2, LEVEL 1 e LEVEL S.

- LEVEL 3: Technologically advaced bandsaw blades, work well even on out-dated machines

- LEVEL 2 : Bandsaw blades for maximum performance

- LEVEL 1: Entry-level bandsaw blades for general purpose, work well even on ineffectual machines

- LEVEL S : Coated bandsaw blades for extreme cutting conditions

Trademarked models and blade categories

CARBIDE BANDSAW BLADES

|

BI-METAL BANDSAW BLADES

|

TCT BANDSAW BLADES

|

3 CT-SIGMA 3 CT-SIGMA

|

3 X-PATH/M42 3 X-PATH/M42

|

|

2 CT-APEX 2 CT-APEX

|

2 X-PATH 2 X-PATH

|

2 TITANFLEX/TCT-POROSET 2 TITANFLEX/TCT-POROSET

|

1 CT-ALPHA 1 CT-ALPHA

|

1 M42 1 M42

|

|

S CT-PRIME S CT-PRIME

|

S X-PATH PRIME/M42 PRIME S X-PATH PRIME/M42 PRIME

|

|

Bandsaw blade selection

Selection criteria:

- BASIC CONDITIONS (Bandsaw machine, type of material for cutting, size and shape, single or layered cutting, customer priority )

- BELT SIZE (Blade width and length are in reference to the bandsaw machine model, the thickness of the belt can vary for the same blade width and length.)

- TOOTH PITCH (The tooth pitch corresponds to the number of teeth per inch (tpi). For the variable pitch the major pitch is expressed first before the minor pitch; for example, a 3 /4 tpi has 3 teet per inch for the major pitch and 4 teeth per inch for the minor. The criteria for choosing the correct pitch is determined by the contact length of the blade in the material being cut, the type of the material, as well as the working parameters of the job. The tpi can be found for each product associated with a useful range for the contact length (mm) in its respective table.

- TOOTH SHAPE. The choice of tooth shape depends on the material being cut and is critical for bimetal products where the cutting edge angles are derived directly from the tooth design. For carbide blades the shape of the tooth does not directly influence the cutting edge angles, which are obtained subsequently in precision grinding processing.

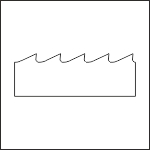

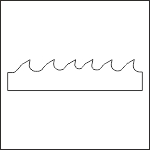

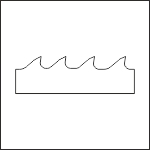

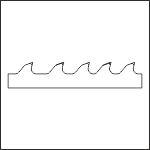

BIMETAL TOOTH SHAPES

LSS (LOW SPACED STANDARD)

LSS (LOW SPACED STANDARD)

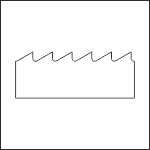

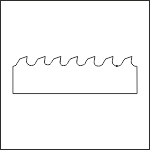

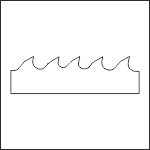

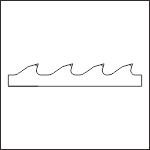

NS (NEUTRAL STANDARD)

NS (NEUTRAL STANDARD)

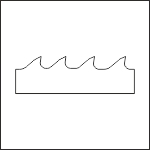

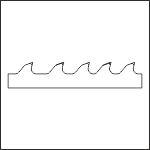

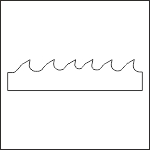

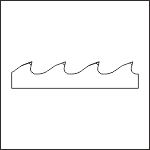

PS (POSITIVE STANDARD)

PS (POSITIVE STANDARD)

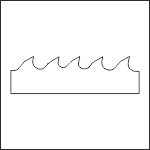

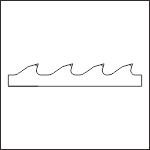

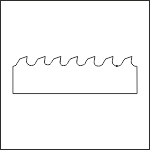

HPS (HIGH POSITIVE STANDARD)

HPS (HIGH POSITIVE STANDARD)

HAS (HIGH ALLOY STANDARD)

HAS (HIGH ALLOY STANDARD)

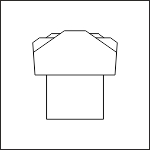

BRS ( BACK REINFORCED STANDARD)

BRS ( BACK REINFORCED STANDARD)

BAS (BACK ACUTE STANDARD)

BAS (BACK ACUTE STANDARD)

CARBIDE TOOTH SHAPES

HAS (HIGH ALLOY STANDARD)

HAS (HIGH ALLOY STANDARD)

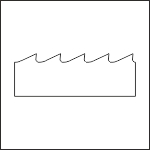

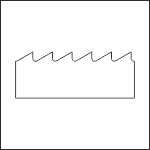

TCT TOOTH SHAPES

VP (VARIABLE PITCH)

VP (VARIABLE PITCH)

FP (FIXED PITCH)

FP (FIXED PITCH)

Geometry set

SEKTOR CUTTING EXPERT has devoloped innovative settings, this being the most important criteria in cutting performance.

CARBIDE TOOTH GEOMETRY

TH (Triple High Geometry)

TH (Triple High Geometry)

VX (Variable Taper Geometry)

VX (Variable Taper Geometry)

HS (High Speed Geometry)

HS (High Speed Geometry)

HRSA (High Resistent Super Alloy Geometry)

HRSA (High Resistent Super Alloy Geometry)

HRC (High Hardness Geometry)

HRC (High Hardness Geometry)

HLO (Interrupted Cutting Geometry)

HLO (Interrupted Cutting Geometry)

TCT GEOMETRY

TC (Triple Chip)

TC (Triple Chip)

SW (Sharp wedge or Soft Wood)

SW (Sharp wedge or Soft Wood)

BIMETAL SETTINGS

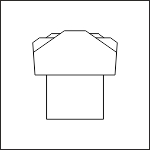

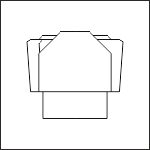

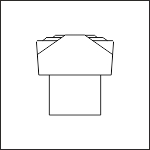

THS (Triple High Straight or Trapezoid High Straight)

THS (Triple High Straight or Trapezoid High Straight)

FHS (Fifth High Straight)

FHS (Fifth High Straight)

SHS (Seventh High Straight)

SHS (Seventh High Straight)

Cutting edge material

The choice of the cutting edge material is strongly influenced by the workability of the material to be cut. Our portfolio is divided into 3 main areas:

- SINTERED CARBIDE Sintered carbide tips of different levels, to maximize the quality of each blade. Blades are available without coating or with coating which can

be in TiAlN , AlTiN, AlTiSiN. Generally recommended for working on metals.

- TCT or SINTERED CARBIDE Tips in sintered TCT for highly abrasive materials and wood with differing grains and fibers.

- HSS BI-METAL Cutting edges available in conventional M42 or in the new sintered X-PATH, characterized by high wear resistance and maximum homogeneity of the material matrix, with which it is possible to split high strength materials in complete safety. M42 and X-PATH are also available in coated versions, generally AlTiN to obtain extended life recommended for the cutting of metal material and wood.

- DEPOSITED CARBIDE OR GRIT CARBIDE Bandsaw blade with continuous or discontinuous deposited carbide for abrasion cutting. Recommended for cutting of metallic, mineral and composite materials.

LSS (LOW SPACED STANDARD)

LSS (LOW SPACED STANDARD) NS (NEUTRAL STANDARD)

NS (NEUTRAL STANDARD) PS (POSITIVE STANDARD)

PS (POSITIVE STANDARD) HPS (HIGH POSITIVE STANDARD)

HPS (HIGH POSITIVE STANDARD) HAS (HIGH ALLOY STANDARD)

HAS (HIGH ALLOY STANDARD) BRS ( BACK REINFORCED STANDARD)

BRS ( BACK REINFORCED STANDARD) BAS (BACK ACUTE STANDARD)

BAS (BACK ACUTE STANDARD) HAS (HIGH ALLOY STANDARD)

HAS (HIGH ALLOY STANDARD) VP (VARIABLE PITCH)

VP (VARIABLE PITCH) FP (FIXED PITCH)

FP (FIXED PITCH) TH (Triple High Geometry)

TH (Triple High Geometry) VX (Variable Taper Geometry)

VX (Variable Taper Geometry) HS (High Speed Geometry)

HS (High Speed Geometry) HRSA (High Resistent Super Alloy Geometry)

HRSA (High Resistent Super Alloy Geometry) HRC (High Hardness Geometry)

HRC (High Hardness Geometry) HLO (Interrupted Cutting Geometry)

HLO (Interrupted Cutting Geometry) TC (Triple Chip)

TC (Triple Chip) SW (Sharp wedge or Soft Wood)

SW (Sharp wedge or Soft Wood) THS (Triple High Straight or Trapezoid High Straight)

THS (Triple High Straight or Trapezoid High Straight) FHS (Fifth High Straight)

FHS (Fifth High Straight) SHS (Seventh High Straight)

SHS (Seventh High Straight)